Peristaltic

pumps have numerous utilizations in industry, however their most basic use is

for high accuracy & purity applications. The reason these pumps are favored

for high virtue applications is that the material being pumped is kept to the

cylinder. The pump never contacts the material and the material never contacts

the pump. This shields the pump from tainting the material and it additionally

shields the material from sullying the pump.

Peristaltic pumps

are utilized frequently for applications

including metering, apportioning and exact general transfer. Since these pumps

offer the uncommon blend of Purity and accuracy, they are the preferred pumps

in numerous applications that incorporate the dosing or exchange of chemicals

and added substances for semiconductor, pharmaceutical and nourishment/food applications.

Since the materials are bound to the tubing, peristaltic pumps just require

negligible upkeep

How do Peristaltic Pumps work?

Peristaltic

pumps got its name because their activity copies the activity in which

sustenance and fluids are exchanged through people and creatures, called peristalsis.

maybe the best exhibition of peristalsis is watching a snake swallow.

Since

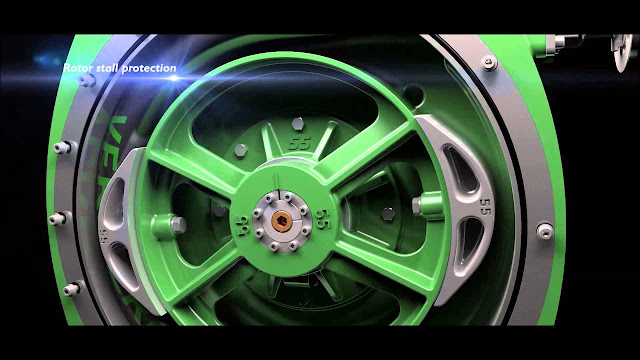

pumps don't have muscles like humans, it is important to utilize rollers to

emulate the opening and shutting of the cylinder on a peristaltic pump and push

materials ahead. The rollers move around on a rotor and close the cylinder

successively. This makes a vacuum at the passage while pushing the materials in

the pump toward the outlet.

The size

of the cylinder or tube, the measure of materials being transported and the

speed of the rollers decide the stream rates of a peristaltic pump. This

enables us to accurately control the speed and the measure of materials moved

by controlling the size of the tubing and the rate of the rollers.

Peristaltic

pumps which is also known as Hose Pumps are accessible in various

setups from the most basic that just pump at one rate to those that are

balanced by computer applications to control careful measures of materials

being pumped, for example, in metering applications.

Benefits of Peristaltic Pumps

We

have just mentioned the principle advantages of peristaltic pumps: they offer absolute

Purity on the grounds that the media being pumped just contacts the cylinder.

Another benefit is that they are accessible in such a large number of various

setups. This enables them to pump a wide assortment of liquids.

Peristaltic

pumps are delegated self-priming. This implies they can move liquids into the pump

from a dry state. It may be awkward to attempt and prime a pump while not to contaminate

the media being transferred. Because of the structure and design of peristaltic

pumps, they are incredibly delicate. This permits peristaltic pumps to exchange

media that are delicate for different structures/designs.

Because

of the variable speed alternatives, peristaltic pumps are prevalent for dosing

applications and exact estimations. Since the liquid does not contact the pump,

the pump requires no cleaning of seals, valves or diaphragms. The main part

that should be cleaned and supplanted all the time is the tubing. This feature

makes the pump low on maintenance and a time saver

Since

a peristaltic pump is non-siphoning, no media are moved back again into the

framework. This is another benefit that makes peristaltic pumps a pump of

choice for metering.

Antlia works is one of the leading Peristaltic Pump manufacturers in

India, Middle-east, Africa & Autralia.

ReplyDeleteShop online from our huge collection of Peristaltic Pumps for suited your medicinal needs. We are a prime supplier of peristaltic pumps.