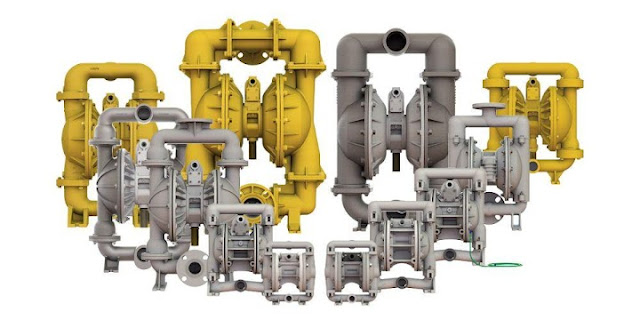

AODD pumps are important, durable, protean, and able of handling nearly any process fluid, from water to thick, unpredictable, and indeed dangerous liquids when duly applied. Then's a introductory manual on AODD pumps and how they serve.

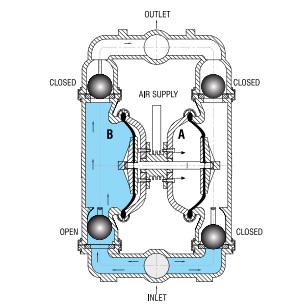

An air-operated double-diaphragm pump is a positive relegation pump that utilizes compressed air by acting on a brace of repaying elastomeric diaphragms that alternatively “ pull and push” fluids or flowable maquillages through a stopcock system/ pumping chambers and out of the pump’s discharge.

Also see : Best Aodd pump suppliers in india

It transports fluid using two diaphragms, each separating the motive air from the fluid being pumped. Each diaphragm has its own pump chamber where it generates expanding and contracting depressions of fixed volume relegation.

The rate is determined by the speed of the pump’s integral air stopcock medium delivering and exhausting air from the air chambers that fill and clear the depressions.

Also read : Best Aodd pump manufacturers in india.

Due to their unique design, AODD pumps are perfect for transferring thin liquids, as well as largely thick or abrasive fluids, with ease.

How does it works ?

Compressed air shifts between the two flexible chambers — each with an bay and outlet check stopcock, as well as a diaphragm mounted on a connecting rod pulling and pushing liquid along.Both diaphragms operate contemporaneously in resemblant oscillation, forcing fluid out through the discharge pipe. The reverse-and- forth stir of the air shifting from one chamber to another workshop in musicale with dyads of suction and discharge check faucets on each chamber. The check faucets alternatively open and close to allow contemporaneous stuffing of one chamber, while the contrary chamber discharges at a speed dependent on the air force.

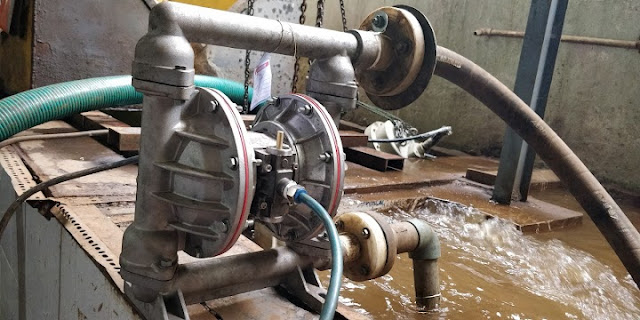

Since these pumps calculate on a force of compressed air to serve, they're generally confined to pumping fluids at pressures at or below those of the available air force. Despite this modest limitation, AODD pumps are known for being robust, protean, and able of handling numerous types of liquids, including largely abrasive, thick, and shear-sensitive fluids, sludge, and slurries. Because of their gentle pumping action, they're also constantly used to pump shear sensitive fluids similar as latex grounded resins, maquillages, coatings, and polymers.

Read about : Aodd pump manufacturers company in India.

Comments

Post a Comment